Why Work with a Full-Service Combustion Equipment Provider?

When it comes to thermal transfer and combustion systems, performance doesn’t begin at startup, it starts with the right partner.

Concept to Commissioning: What a Full-Service Partner Delivers

Designing a system means ensuring that the system operates reliably, meets compliance standards, integrates with existing infrastructure, and can be maintained efficiently over time. That’s why more industrial facilities are turning to full-service combustion partners, not just part suppliers or design consultants.

So, what does “full-service” actually mean? And more importantly, what does it deliver?

1. Integrated System Design Aligned with Your Operation

A true full-service partner doesn’t just provide a burner or a control panel, they deliver a combustion solution designed for your facility’s process, load profiles, and infrastructure constraints.

This starts with:

- Detailed load and emissions analysis

- Compatibility assessments for legacy systems

- Right-sized equipment selections to prevent overengineering

- CAD-based layout and mechanical interface planning

Results: You get a purpose-built system, not a generic spec.

2. Procurement and Vendor Coordination Simplified

With multiple OEMs, sub-vendors, and shifting specs, procurement for combustion systems can quickly become complicated and confusing. A full-service provider acts as your single point of accountability, streamlining sourcing, ensuring part compatibility, and reducing lead time risk.

Your full-service provider manages:

- Component selection and specification

- Vendor qualification and pricing transparency

- BOM integrity and supply chain coordination

Results: Fewer delays, reduced administrative overhead, and total part traceability.

3. Factory Testing and Pre-Commissioning Quality Checks

Systems that arrive on-site should be plug-and-perform, not assemble-and-hope. Full-service partners conduct in-house testing to validate functionality and prevent field surprises.

Your full-service provider conducts:

- Skid-mounted or panel-integrated dry-run testing

- Documentation and I/O verification before shipment

Results: Reduced risk during commissioning and minimized installation errors.

4. On-Site Commissioning and Technical Support

System startup isn’t the time to discover integration gaps or tuning issues. A full-service partner is on-site, overseeing installation, burner startup, system tuning, and personnel training.

Services include:

- Burner and control loop tuning

- Emissions verification

- Operator walkthroughs and safety validation

Results: Faster time to operation, verified performance, and trained personnel from Day One.

5. Post-Install Support and Lifecycle Service

Combustion systems require ongoing attention, from parts replacement to compliance adjustments. A full-service partner stays involved with you long after commissioning.

You can count on them for:

- Spare parts forecasting and stocking programs

- Remote diagnostics and technical assistance

- Preventive maintenance support

- Retrofit or system upgrade planning

Results: Less unplanned downtime, longer asset life, and fewer surprise failures.

ECS Provides End-to-End Support

When you’re managing critical combustion equipment, isolated support doesn’t cut it. Partnering with Engineered Combustion Systems as your full-service provider means:

✔ One point of contact

✔ Consistent documentation and system knowledge

✔ Higher ROI through optimized performance and support

✔ Fewer finger-pointing scenarios when issues arise

Ready to consolidate your combustion needs under one proven team?

Talk to ECS about how our end-to-end solutions, from engineering through emergency parts, can simplify your operations and future-proof your system. Contact us today!

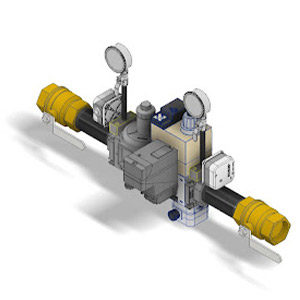

ECS Announces the Expansion of Hot and Chilled Water Control Systems

ECS Announces the Expansion of Hot and Chilled Water Control Systems  ECS Offers New Gas Train Quick Ship Program

ECS Offers New Gas Train Quick Ship Program  ECS Expands Our Service Team

ECS Expands Our Service Team  ECS Launches Combustion Plus Online Shopping Site

ECS Launches Combustion Plus Online Shopping Site  ECS Launches Newly Expanded Website

ECS Launches Newly Expanded Website